Table of contents

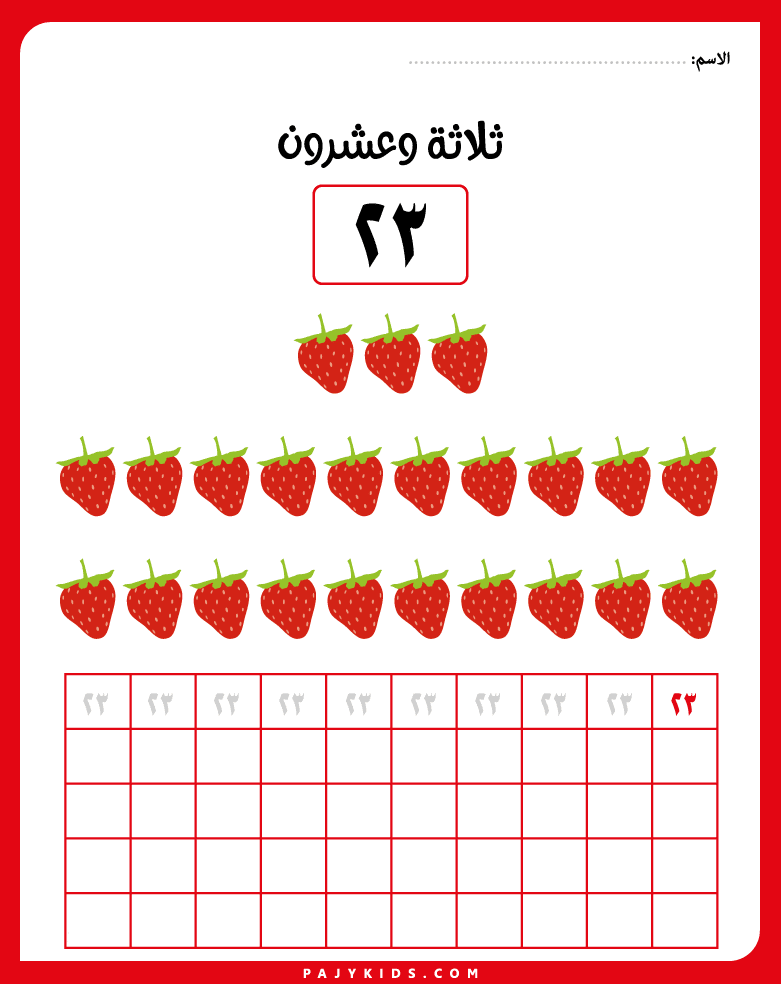

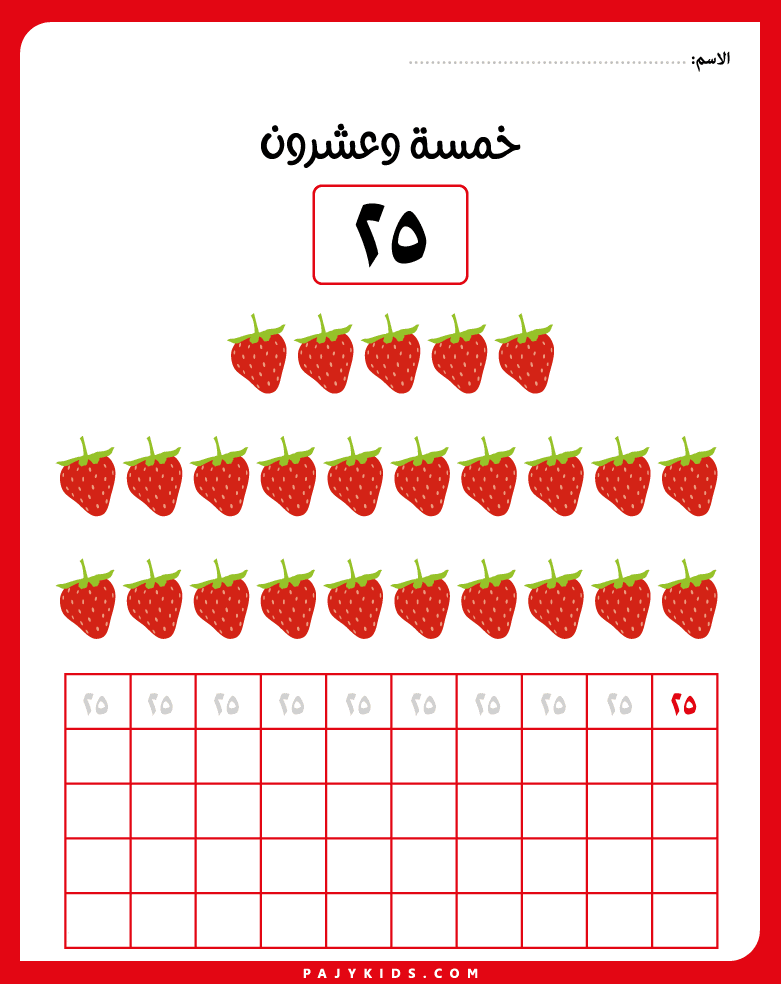

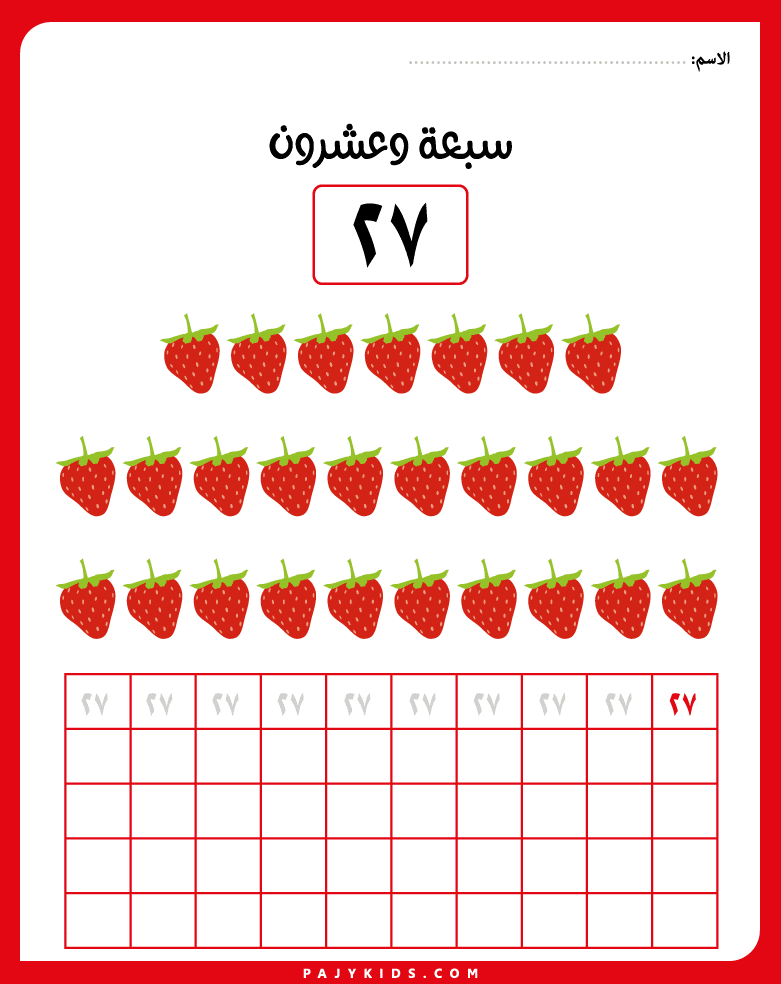

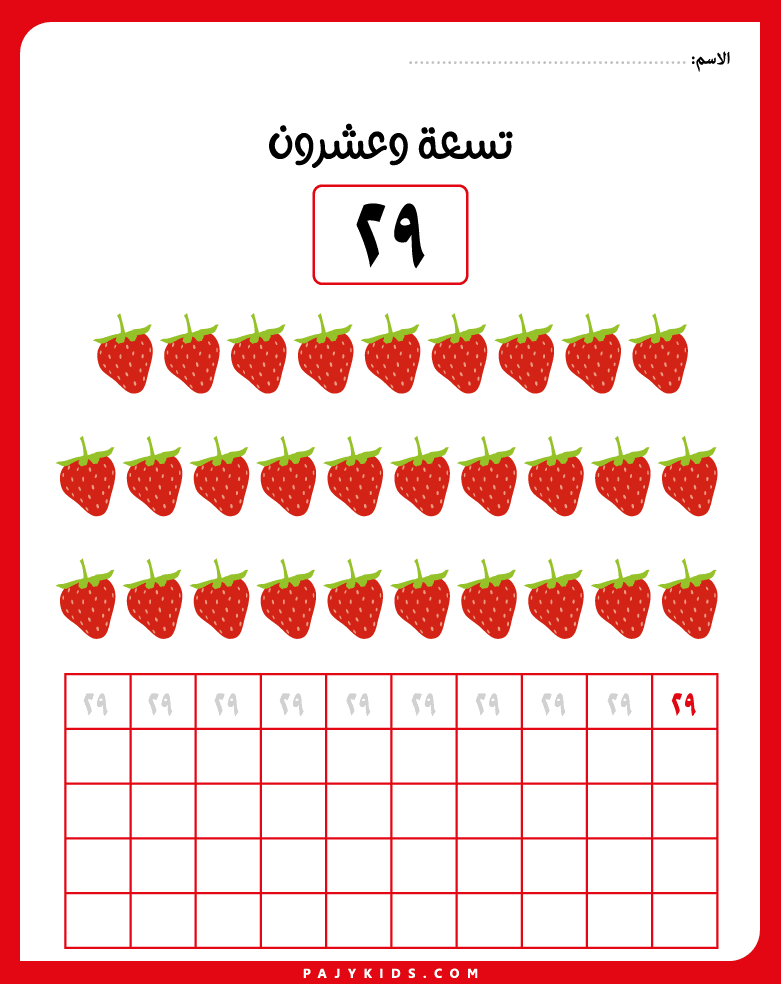

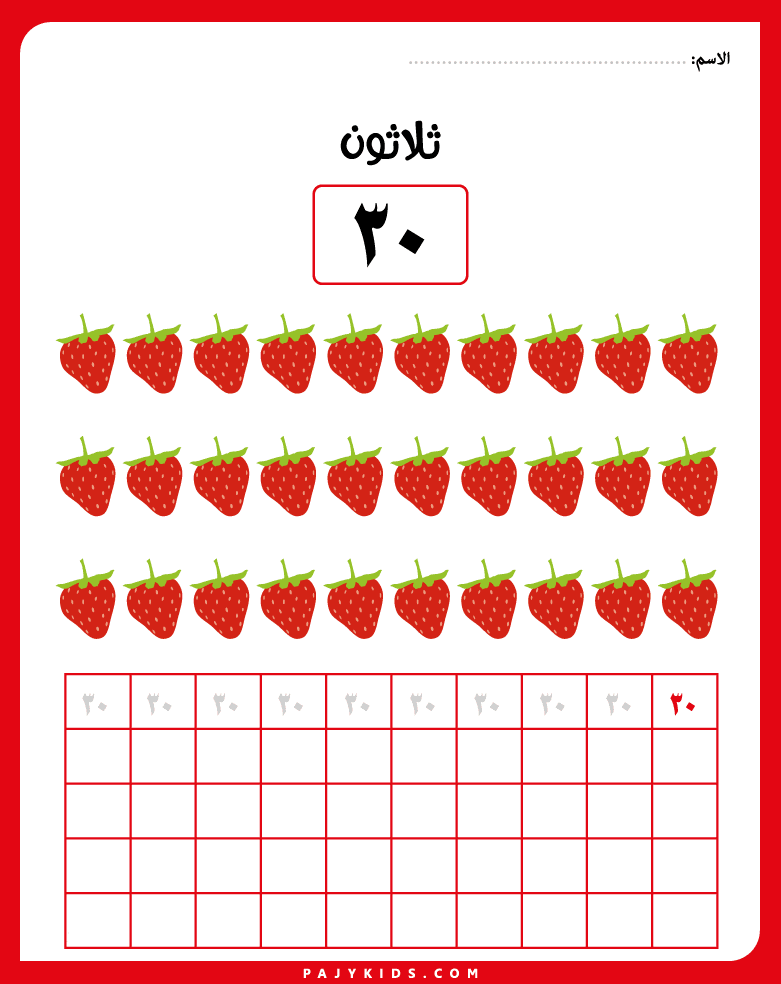

Early number learning depends heavily on repetition, structure, and age-appropriate activities. arabic numeration worksheets designed for tracing practice provide kindergarten children with a clear and supportive pathway to recognize, write, and understand numbers. By combining visual guidance with hands-on movement, these worksheets help young learners build confidence while developing essential pre-writing and numeracy skills.

Arabic numeration as a Core Skill in Early Education

Understanding number symbols is one of the first academic challenges children encounter. Tracing worksheets introduce arabic numeration in a controlled and gradual way, allowing children to focus on number shape and direction before attempting independent writing. This approach strengthens number recognition and lays the groundwork for counting, sequencing, and basic mathematical operations in later grades.

How Tracing Worksheets Support Fine Motor Development

Kindergarten learners are still refining the small muscles in their hands and fingers. Tracing activities require controlled movements that improve pencil grip, hand strength, and coordination. As children repeatedly trace numbers, they gain better control and accuracy. Over time, working with arabic numeration becomes less effortful and more natural, supporting smoother transitions to freehand writing.

Visual Structure and Learning Consistency

Well-designed worksheets rely on consistency and clarity. Clear outlines, directional arrows, and adequate spacing help children understand how each number is formed. Visual repetition reinforces memory, while structured layouts reduce confusion. When arabic numeration worksheets follow a predictable pattern, children feel secure and more willing to engage in regular practice without frustration.

Building Confidence Through Progressive Practice

Effective tracing worksheets move from simple to more complex tasks. Children may start with large, bold outlines and gradually progress to smaller or partially guided numbers. This progression allows them to experience success at every stage. With repeated exposure to arabic numeration, children build confidence, which positively influences their motivation and overall learning attitude.

Using Worksheets at School and Home

Consistency across learning environments significantly enhances results. Teachers can introduce tracing worksheets in the classroom, while parents reinforce the same skills at home through short, relaxed practice sessions. When children encounter arabic numeration in both settings, learning becomes more stable, familiar, and deeply rooted.

Arabic Numeric Learning for Kindergarten

Tracing worksheets are more than simple practice sheets; they are foundational learning tools. When thoughtfully designed and used consistently, arabic numeration worksheets support motor development, number recognition, and early mathematical understanding. By integrating structured practice with encouragement and repetition, educators and parents can help kindergarten children build strong, lasting number skills.