Table of contents

Introducing new math concepts in kindergarten requires clarity, patience, and carefully structured activities. addition with regrouping is an advanced step compared to basic addition, but when presented in a simplified and visual way, young learners can begin to understand the idea behind it. With the right approach, children learn that numbers can be combined even when values exceed a single place, building early confidence and number sense.

Understanding the Concept Behind Regrouping

Before children solve problems, they need to understand what regrouping means. At its core, regrouping teaches that when a group becomes too large, it can be reorganized into a new group. Using simple language and concrete examples helps children see how numbers work together. This conceptual understanding prevents confusion and ensures learning is meaningful rather than mechanical.

Addition with Regrouping Using Visual and Concrete Models

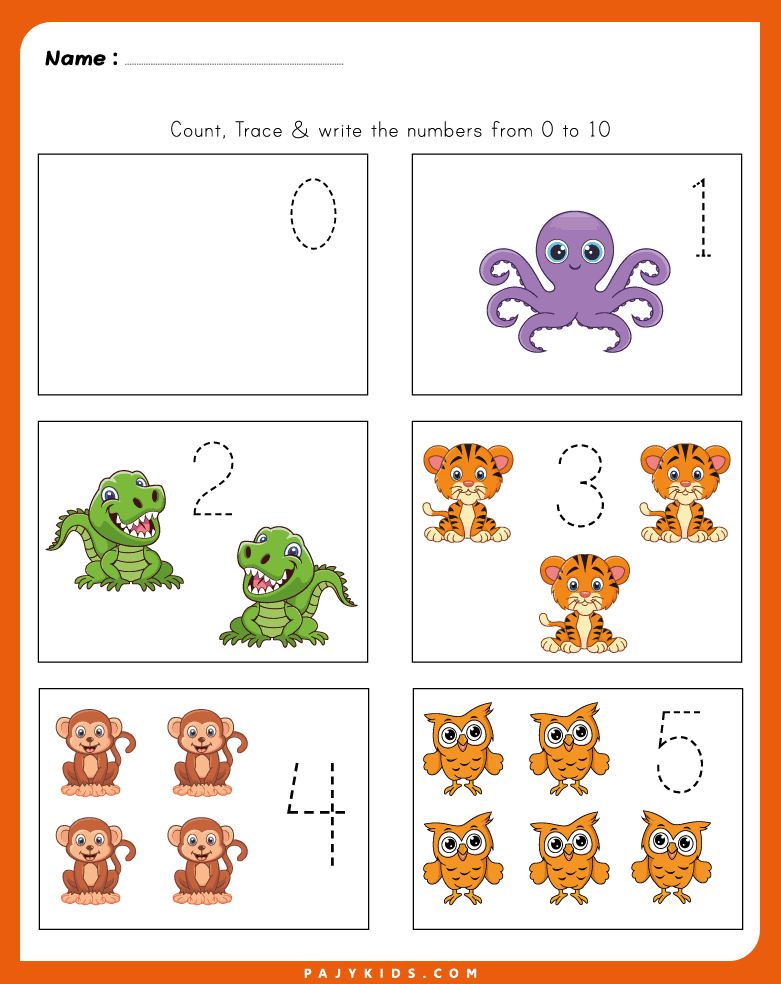

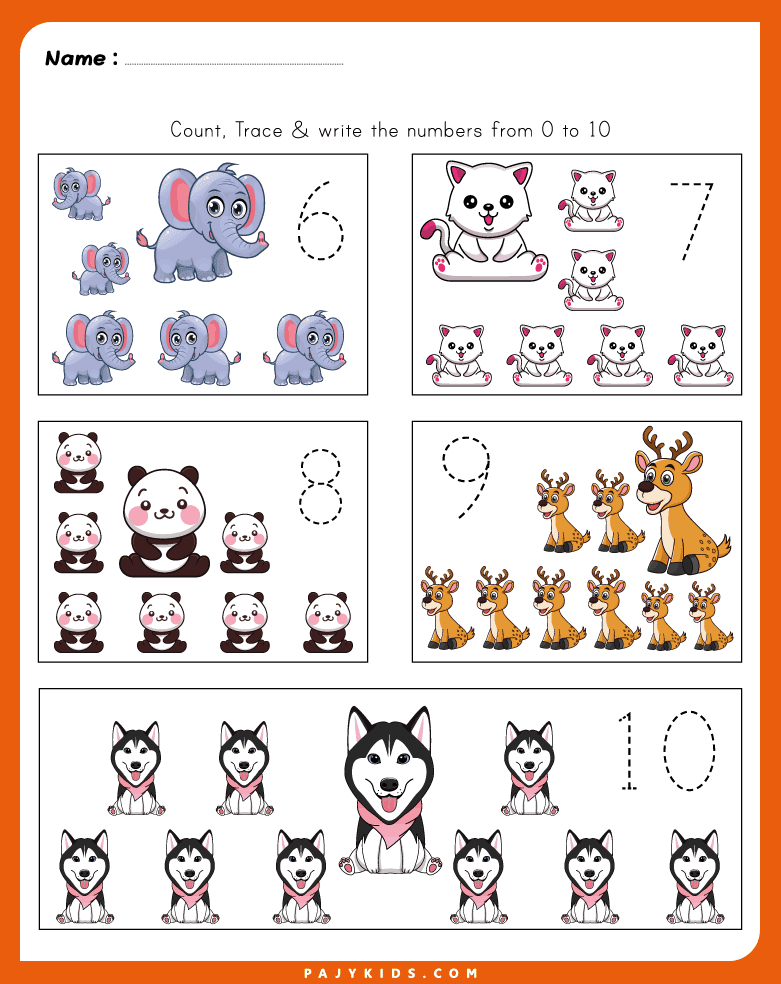

Visual aids play a critical role in teaching addition with regrouping to young learners. Tools such as counters, blocks, and place-value charts help children see how ones turn into tens. When children physically move objects, the abstract idea becomes tangible, making it easier to grasp and remember.

Building Readiness Through Step-by-Step Practice

Kindergarten learners benefit from gradual progression. Practice should begin with familiar numbers and clear guidance, moving slowly toward regrouping examples. Breaking each problem into steps allows children to follow along without feeling overwhelmed. Repeated exposure to addition with regrouping in small doses strengthens understanding and reduces frustration.

Developing Fine Motor and Thinking Skills Together

Math practice at this stage supports more than numerical knowledge. Writing numbers, drawing groupings, and circling answers help develop fine motor skills and concentration. As children work through addition with regrouping, they also improve attention, sequencing, and problem-solving abilities, which are essential across all learning areas.

Fractions for Kindergarten: Mastering Basic Concepts with Visuals

Supporting Learning at School and Home

Consistency reinforces understanding. Teachers introduce structured activities in the classroom, while parents can support learning at home using simple objects like toys or snacks. Practicing addition with regrouping in different environments helps children connect learning to real life and strengthens long-term retention.

Early exposure to regrouping builds a strong foundation for future math success. When addition with regrouping is taught through visual tools, clear steps, and supportive practice, kindergarten children can develop confidence and curiosity toward more complex math concepts. With patience and the right strategies, this skill becomes an achievable and positive learning experience.